Having a straight rear end housing is very important to the overall handing of your race car. Just as you carefully align your front end so the wheels are pointing in the right direction, the same needs to be done with the rear housing. I would venture to bet that most race cars have a bent rear end housing. The reason for this is most people have no way of accurately checking. When purchasing a new rear end racers naturaly assume that it is straight. Think again! Even if straight when purchased, it will probably bend when you weld or tack weld the brackets to it.

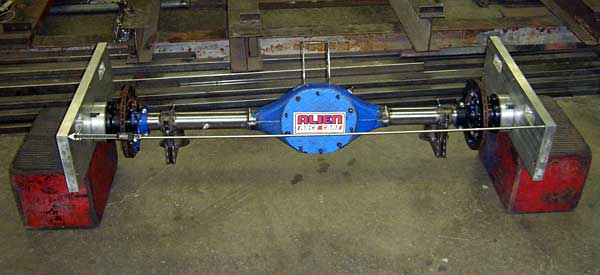

I used to purchase lots of pre-manufactured housings and just assumed they were straight. One day I checked a new order of 4 housings I had purchased, and found that all were bent. The minimum error was 1/4" out and the worst was a 1/2". Either way was unacceptable. At that point I decided to get into the rear end business. I have made a jig to build them, bought a Mittler Bros. alignment fixture and a set of alignment plates, with a precision custom built vernier calliper. Now all our rear ends are built and aligned to within .008". With our equipment we can individually align each wheel perfectly. When this is done you can set your rear end housing in your chassis so that you can perfectly align the front with the back.

Having the rear end aligned is just as important as the front end alignment, maybe even more so. All the power is applied through the rear housing, if it isn't aligned properly the rear end will have a mind of its own and drive the car all over the place. If you don't have the proper equipment to check your housing for straightness there is a fairly quick way of doing it. Take the housing out of the car, pull the axles out if it is a floating assembly. Leave the wheels and tires on, block the wheels so they can't roll, string a tape measure across the top of the two tires. Mark the tape measure with some masking tape so you can tell if the tape moves. Now rotate the center section 360 degrees and watch to see if the tape moves. If it does, you can tell which side is longer and which is shorter. Determine where the rear end is the longest. Now you must heat shrink the axle tubes to pull the rear end straight.

A word of caution, if your rear end has more than a 1/4 "of deflection it will need an axle tube replaced. If it is under 1/4" you can heat shrink it. First you must determine the longest side, then get a torch and heat up an area the size of a silver dollar so that it glows red hot. Now immediately quench that area with some cold water until the area is back at room temperature. Remeasure and you should see a change in the overall length. If you decide to straighten a rear end housing this way you should get it so the overall deflection is less than 1/32". This is not the most accurate way to do it but will work if you don't have the proper alignment tools.